Texa e-Powertrain

italian innovation

for sustainable mobility

With a strong commitment to sustainable innovation, TEXA e-Powertrain positions itself as a global point of reference in electric and hybrid drive, proudly pursuing the tradition of Made in Italy in the automotive industry.

1992

TEXA was founded in 1992 by the current President Bruno Vianello.

With over 1,000 employees, seven subsidiaries in the world and continuous investments in research and development, today it is one of the key actors worldwide in the production of diagnostic and remote diagnostic devices, A/C charging stations and exhaust gas analysers.

2018

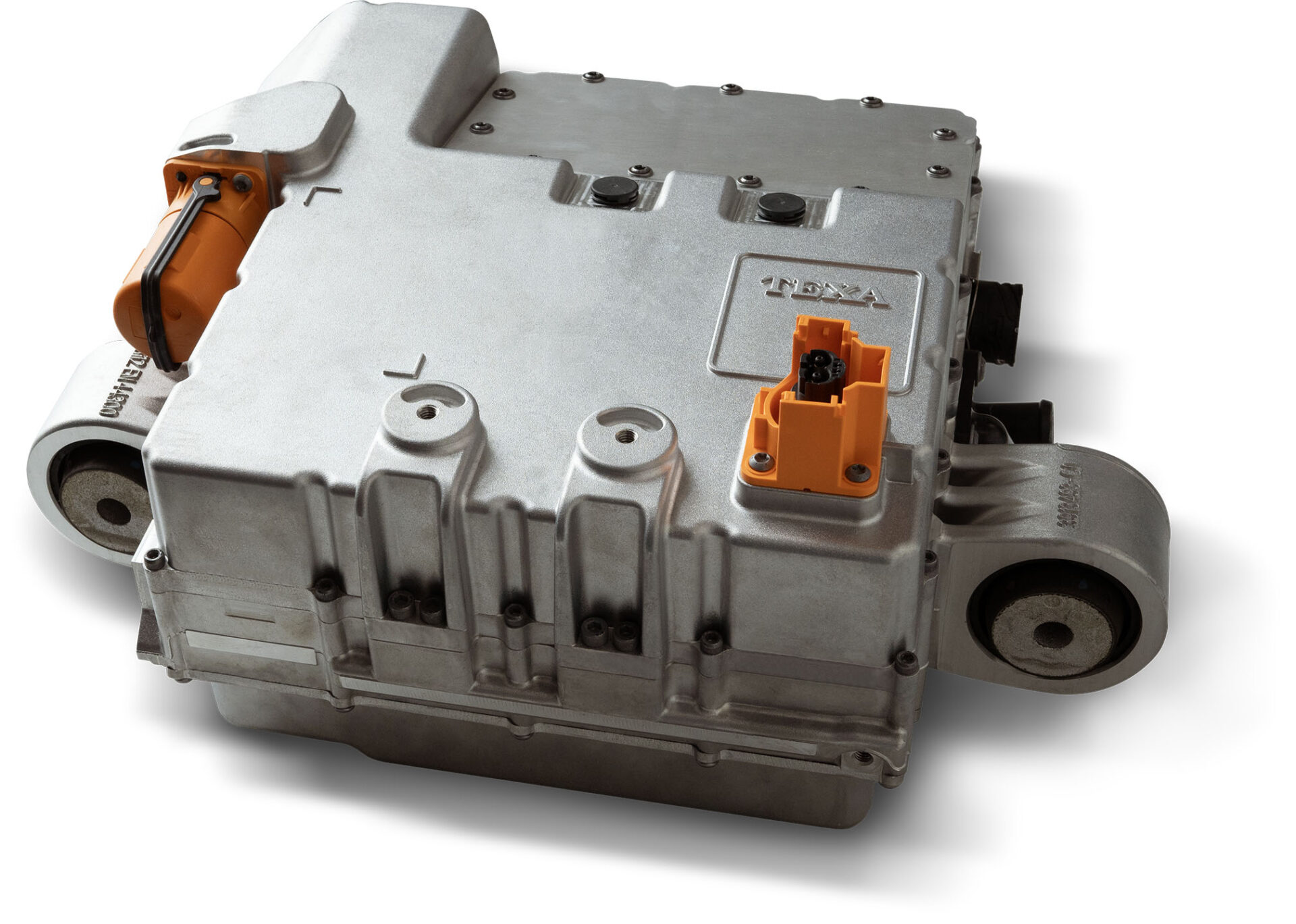

In 2018 e-Powertrain was created to follow the change towards electric mobility. It is a division dedicated exclusively to the design and production of innovative axial flux electric motors, inverters and vehicle control units for electric and hybrid vehicles.

2023

In 2023 the new ultramodern e-Powertrain plant was inaugurated, where approximately one hundred technicians and professionals are employed and first-equipment components are produced for the Lamborghini Revuelto and Temerario models, other than for other important supercar manufacturers.

TEXA is among the few companies in the world to offer a permanent magnet synchronous motor with an axial flux architecture. This configuration, with two disc rotors and liquid cooling, guarantees:

- EXTREME COMPACTNESS

- REDUCED WEIGHT

- HIGH REACTIVITY

- EASY INTEGRATION IN VEHICLES

TEXA’s inverter, compact and liquid-cooled, uses IGBT modules and, soon, SiC MOSFETs and GaN (gallium nitride) components for greater efficiency especially in urban areas.

The production lines use advanced technologies such as the Double Side Cooling (DSC), allowing the creation of 400, 600 and 800 Volt inverters.

e-Powertrain is designed in sections of approximately 1,000 square meters to host distinct automative customers in a confidential manner with their own clean room, each equipped with a filtration technology that allows constantly checking the atmospheric pressure, the humidity and the particle pollution, for assembly and testing.

It also includes the Automotive Engineering Laboratory, which manages the design of new systems and lines dedicated to e-Powertrain products, the Prototype Laboratory and the Technological Laboratory that contains the tools used for the chemical and morphological characterisation of the particulate collected during the studies and measurement campaigns on the components.

The structure is completed by a further area called “Incoming Quality Inspection” for the quality check of the incoming raw materials.

TEXA also has two important R&D centres in Turin and Bologna.

SAFETY, QUALITY AND CERTIFICATIONS

The plant is designed based on the highest safety and quality standards.

EPA (ELECTROSTATIC PROTECTED AREA)

ESD CHECK FOR DELICATE COMPONENTS

REGULATED ACCESS WITH PERSONAL PROTECTIVE EQUIPMENT

MEASURING STATIONS BUILT INTO THE ENTRANCE TURNSTILES

CERTIFICATIONS OBTAINED

ISO/IEC 27001

TISAX

IRP

IATF 16949

Work with us

FIRMWARE DEVELOPER

Planning operator junior

Manufacturing test engineer

Manufacturing TPMG developer

TEXA e-Powertrain is continuously searching for motivated and talented resources, ready to contribute to electric drive innovation. If you want to be part of a project, check out our open positions.

Send your CV and join our team.

TEXA e-Powertrain is a project by TEXA S.p.A, one of the world’s leading companies in the design, industrialisation, and manufacturing of multi-brand diagnostic tools, exhaust gas analysers, stations for air conditioning maintenance, and devices for remote diagnosis, for passenger cars, motorcycles, trucks, agricultural and construction vehicles, boats.